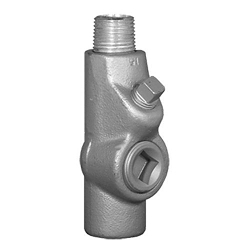

APPLETON EYS216 3/4 MALE SEAL-OFF

Product Overview

These Appleton® sealing fittings minimize the passage of gases and vapors and prevent the passage of flames from one portion of a conduit system to another. They prevent pressure piling within the conduit system and contain any explosion that occurs. These models in the EYS series provide a close turning radius and can be used for sealing vertical or horizontal conduit runs.

- Attributes

- Documents

- Application

- Item Features

- Standards

BrandAppleton®

ColorGray

Country of OriginMX

Dimensions3.69 in L x 1.5 in W

FinishTriple Coated

Manufacturer NameEmerson Electric

MaterialGrayloy-Iron

SeriesEYS

Size3/4 in

Suitable For Use WithIMC/Threaded Rigid Metallic Conduit

TypeDust-Ignitionproof Explosionproof Raintight

For prevent passage of gases, vapors or flames from one portion of conduit system to another

- Smooth, rounded integral bushing in each hub to protect conductor insulation

- Accurately tapped, tapered NPT threads for tight, rigid joints and ground continuity

- Removable nipple in male sealing fitting may be used interchangeably in top or bottom hub

- Large opening for damming and filling

- Restrict any explosion to the sealed off enclosure

- Required in Class I, Division 1 and 2 locations within 18 in of enclosures containing apparatus that may cause arcs, sparks or high temperatures

- Required in Class I, Division 1 and 2 locations where 2 in or larger conduit enters enclosure, fitting housing terminals, splices or taps

- Required in Class I, Division 1 and 2 locations at the boundary where conduit leaves classified location

- Required in Class I, Division 1 and 2 locations where two or more enclosures are connected by 36 in or less conduit, seal must be located within 18 in of either enclosure

- Required where cables which exceed rate of gas or vapor transmission permitted for seals are used in Class I, Division 2 locations

- Tapered MNPT X tapered FNPT connection

- 25% fill vertical and horizontal conduit sealing fittings for close turning radius

- Chromate/epoxy powder coated/zinc electroplated finish

UL 886|UL 1203 File No. E10444|CSA C22.2 No. 30|CSA 065181|Class I, Groups A, B, C, D|Class II, Groups E, F, G|Class III